Introduction to Custom Label Printing Technology

What is custom label printing?

Custom label printing is more than just adding branding to a product—it’s a critical tool for differentiation, compliance, and consumer engagement. In a competitive marketplace, well-designed product labels help brands stand out on store shelves, communicate essential product information, and connect with consumers on a deeper level.

Modern label technology has advanced far beyond basic printed stickers. Today, brands can leverage smart labels, digital printing, RFID tracking, and variable data printing to create interactive, personalized, and highly functional packaging solutions. The right label enhances brand recognition, ensures regulatory compliance, and even improves supply chain efficiency.

Why custom label printing enhances product differentiation

Today’s consumers have more choices than ever, making packaging and labeling a critical factor in purchasing decisions. High-quality, strategically designed labels help brands:

- Stand out in a crowded marketplace – Shelf appeal matters. Visually striking labels grab attention and help brands compete.

- Leverage personalization and limited-edition packaging – Custom label printing allows brands to create seasonal packaging, localized variations, and promotional editions.

- Tell a compelling brand story – Labels are more than just product descriptions; they’re a way to communicate values, quality, and identity to consumers.

Why high-quality product labels are essential for branding and compliance

Beyond aesthetics, custom labels serve a functional purpose:

✅ Branding: Consistent color, typography, and material choices build strong brand recognition.

✅ Compliance: Food, beverage, pharmaceutical, and regulated industries require labels that meet legal standards for ingredient lists, safety warnings, and traceability.

✅ Consumer Trust: High-quality labels signal premium product quality, while smart labels provide transparency on sourcing, sustainability, and authenticity.

How evolving printing technologies are reshaping product packaging

New advances in label printing technology are helping brands enhance efficiency, improve sustainability, and create more interactive experiences. Innovations such as:

- Digital label printing – Faster production times, cost-effective short runs, and greater customization.

- Smart label technology – Integrating QR codes, NFC, and RFID tracking to provide real-time product data and enhance consumer interaction.

- Sustainable label materials – The rise of biodegradable labels, water-based inks, and recyclable packaging solutions.

Understanding Options in Label Printing Technologies

Choosing the right label printing technology is essential for balancing cost, quality, and scalability. Each printing method offers unique benefits, and selecting the best fit depends on factors such as order volume, material selection, turnaround time, and compliance requirements.

Understanding key label printing terminology

Before diving into specific printing methods, it’s important to understand a few key terms that impact custom label production:

- Substrate: The material a label is printed on, such as paper, plastic, or metallic film.

- Adhesive: The bonding agent that determines whether a label is permanent, removable, or repositionable.

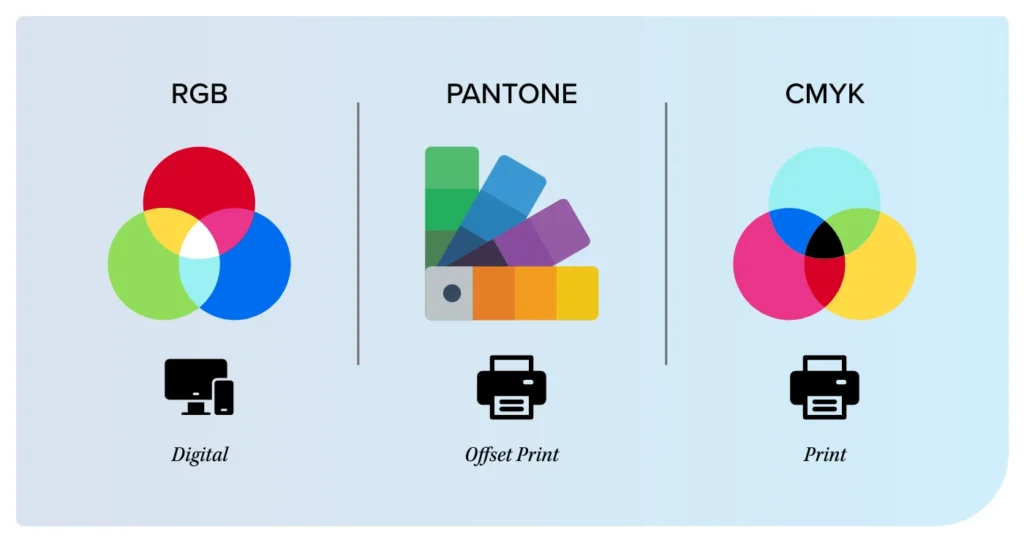

- CMYK vs. PMS Colors: CMYK (Cyan, Magenta, Yellow, Black) is used for full-color digital printing, while Pantone Matching System (PMS) ensures precise brand color consistency.

- Variable Data Printing (VDP): A technology that allows unique data (e.g., serial numbers, barcodes, personalization) on each label within a print run.

Cost, speed, and quality considerations

When evaluating custom label printing methods, brands must weigh three key factors:

✅ Cost: Setup fees, material choices, and print run sizes all impact final pricing.

✅ Speed: Digital methods offer faster turnaround, while traditional printing excels in high-volume efficiency.

✅ Quality: Factors like color consistency, durability, and special finishes define the final product’s look and feel.

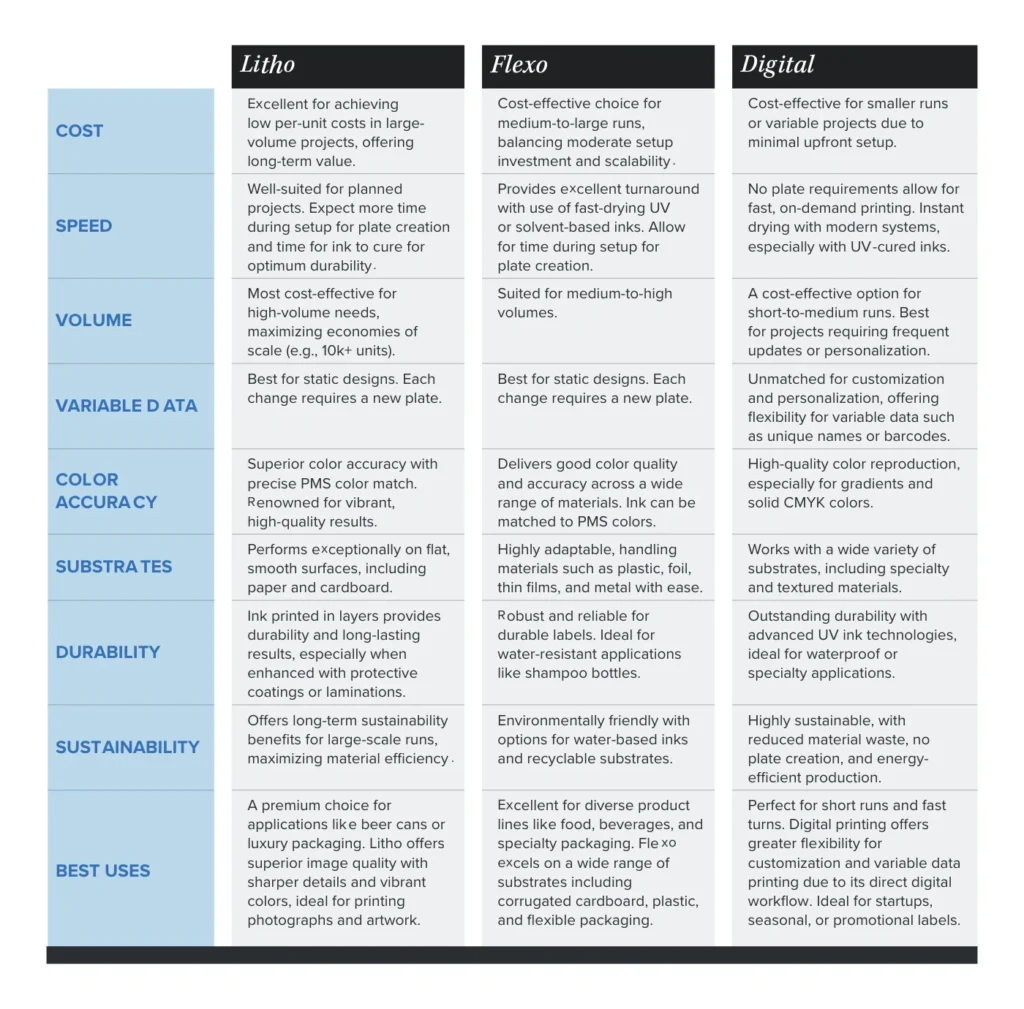

Comparing digital vs. traditional printing

Choosing between digital, flexographic, and lithographic printing depends on your production needs, budget, and quality expectations.

- Digital printing is best for small-batch, high-customization, and fast-turnaround needs.

- Flexographic printing is ideal for large print runs with consistent quality and specialty materials.

- Lithographic printing delivers premium finishes but requires high-volume production to be cost-effective.

Matching label technology to industry regulations

For brands in regulated industries, label printing technology must align with compliance and durability standards.

- Food & Beverage: Labels must withstand moisture, refrigeration, and handling while meeting FDA regulations.

- Pharmaceutical & Medical: Precise printing is required for dosage, safety, and tracking information.

- Cosmetics & Personal Care: Labels should be oil-resistant, tamper-evident, and fade-resistant for extended shelf life.

By selecting the right printing technology, materials, and finishes, brands ensure that their labels remain compliant, durable, and visually appealing.

Innovations in Custom Label Printing

Advancements in label printing technology are reshaping the way brands design, print, and apply labels. From smart labels that enable digital interactions to sustainable materials that align with eco-conscious consumers, today’s innovations offer new opportunities for efficiency, customization, and consumer engagement.

The rise of smart labels and interactive packaging

Smart labels bridge the gap between physical products and digital experiences, offering consumers instant access to additional information, promotions, and authentication features.

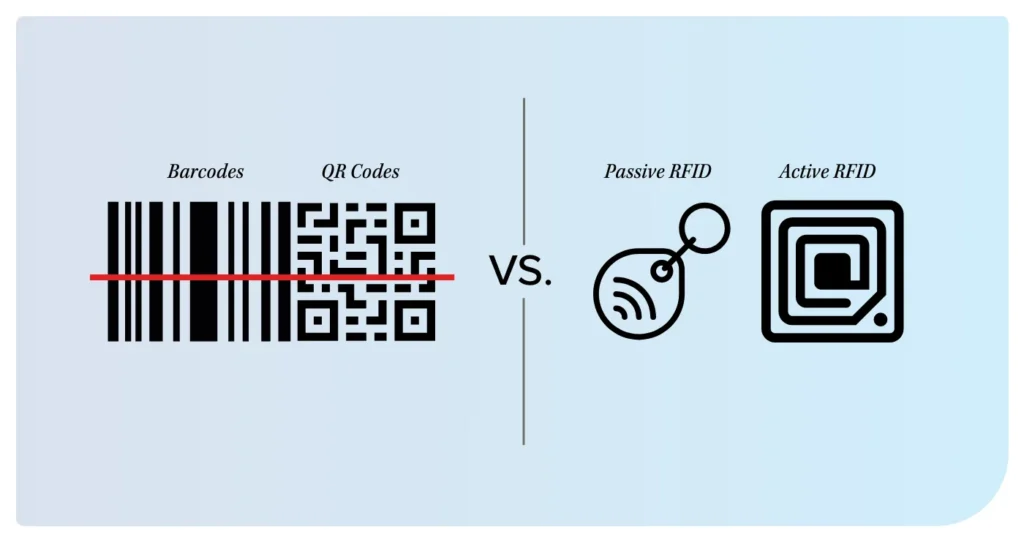

What is a smart label? A smart label integrates RFID (Radio Frequency Identification), NFC (Near Field Communication), or QR codes into packaging, allowing customers to interact with products in real time.

How do smart labels work?

- QR Codes: Direct consumers to websites, videos, or promotions.

- RFID Labels: Automate inventory tracking and improve supply chain visibility.

- NFC Tags: Enable tap-and-go experiences, such as instant reordering or authentication.

Examples of smart labels in product packaging

Brands are already leveraging smart label technology to improve customer experience, transparency, and product security:

- Dove Shower Sensor Body Wash: A temperature-sensitive label that changes color when water is too hot.

- Frederick Wildman Wines: AR-enhanced labels that offer guided tastings and food pairing suggestions via smartphone scan.

- YUNI Beauty: NFC-enabled labels that provide tutorials and product information with a simple tap.

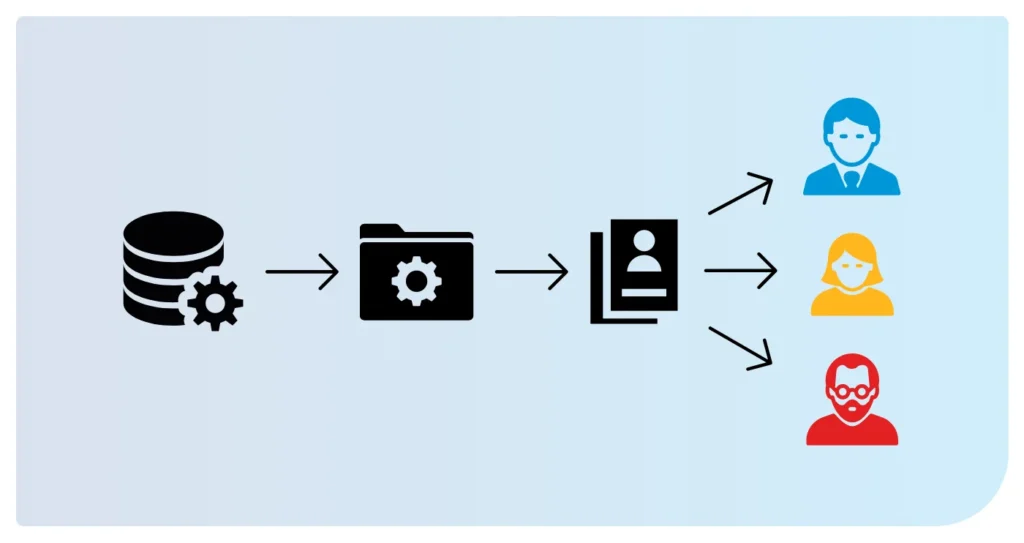

Variable data printing for mass customization

Brands are increasingly turning to Variable Data Printing (VDP) to personalize packaging at scale. This technology enables:

- Personalized promotions – Unique discount codes or customer-specific messaging.

- Localized packaging – Region-specific languages, regulations, or cultural adaptations.

- Product traceability – Batch tracking for recalls and authenticity verification.

RFID and QR code labels for interactive engagement

Smart labels aren’t just for consumer convenience—they also enhance supply chain efficiency and security:

✅ Inventory accuracy – RFID-enabled labels streamline warehouse management.

✅ Anti-counterfeiting measures – Brands use QR codes to verify authenticity.

✅ Sustainability tracking – Smart labels help customers understand product origins and recycling options.

Sustainability in label printing

As eco-conscious purchasing grows, brands are prioritizing sustainable label materials and printing processes to reduce their environmental footprint. Advances in label technology are making it possible to balance high-quality printing, durability, and sustainability without compromise.

Consumers are demanding change—60% of shoppers say they’d pay more for a product with sustainable packaging. Brands that embrace eco-friendly label solutions are not only reducing waste but also gaining a competitive edge.

Key innovations driving sustainable label printing include:

- Recyclable or biodegradable materials – Reducing plastic waste in packaging while maintaining durability.

- Water-based inks – A cleaner alternative to solvent-based printing.

- Compostable adhesives – Ensuring labels break down without leaving residue.

Some brands are going even further with cutting-edge solutions like edible packaging. Imagine a product where the label or packaging itself is safe to consume, leaving zero waste behind. This innovation, already emerging in food and beverage applications, highlights how technology is redefining what’s possible in sustainable design.

With consumer demand and industry regulations increasing, investing in sustainable label solutions isn’t just good for the planet; it’s a smart business decision.

Color Management Technology for Consistent Label Printing

Consistent color across all SKUs, product lines, and packaging formats is critical for maintaining brand identity and consumer trust. Without proper color management, labels can appear mismatched, leading to a disjointed brand presence on store shelves. Advanced color control technology ensures that every printed label matches brand standards with precision.

Why color consistency matters in label printing

Color plays a major role in brand recognition and consumer perception. Inconsistent colors can:

???? Weaken brand identity – Consumers expect uniformity across packaging.

???? Reduce shelf appeal – Mismatched tones can make products look outdated or unprofessional.

???? Cause compliance issues – Regulated industries require precise color accuracy.

Maintaining color accuracy across different printing technologies and materials requires calibrated systems and expert oversight—a key differentiator of Epsen Hillmer’s printing process.

Understanding color models in label printing

Different printing processes use different color models to produce vibrant, accurate labels.

- Pantone Matching System (PMS): Industry standard for spot colors that ensure precise brand consistency.

- CMYK (Cyan, Magenta, Yellow, Black): Ideal for full-color printing with a broad spectrum of hues.

- RGB (Red, Green, Blue): Used for digital displays, not recommended for printed labels.

Ensuring brand consistency across SKUs and product lines

To maintain consistency, brands should:

✅ Work with a label printing partner experienced in color matching

✅ Use high-quality substrates that support color vibrancy

✅ Regularly review printed proofs and digital mockups

Enhancing Labels with Advanced Finishes

A well-designed product label does more than display information—it creates a tactile and visual experience that influences purchasing decisions.

Why is this important? 72% of American consumers say that packaging design influences their buying choices.

Advanced finishes help brands add a premium touch, improve durability, and stand out on the shelf.

Luxury finishes that elevate brand perception

Consumers often associate premium packaging with higher-quality products. Adding advanced finishes to labels can:

- Increase perceived value – Embossing, foil stamping, and specialty coatings create a high-end look.

- Enhance shelf impact – Unique textures and finishes make products stand out in crowded retail spaces.

- Improve durability – Protective coatings prevent fading, smudging, and wear over time.

Types of advanced label finishes

- Foil stamping – Adds metallic elements for an upscale, eye-catching effect.

- Embossing and debossing – Creates raised or recessed designs for a textured, premium feel.

- Spot UV and matte finishes – Highlights specific areas for contrast and dimension.

- Textured and specialty coatings – Enhances durability while improving visual appeal.

Customization & Flexibility in Label Printing

Every brand has unique packaging needs, and a one-size-fits-all approach to label printing doesn’t work. The ability to customize labels based on design, materials, finishes, and production methods ensures that brands can create packaging that aligns with their identity and market demands.

Choosing the right label printing partner for your brand

Not all label printing companies offer the same level of customization and flexibility. Brands should look for a printing partner that provides:

- Custom label shapes and sizes – Ensuring labels fit unique packaging designs.

- Material versatility – Options for paper, plastic, metallic, and specialty substrates.

- Scalability – The ability to handle both small test runs and large-scale production.

- Fast turnaround times – Reliable production schedules to meet tight deadlines.

Comprehensive label solutions from design to production

An effective label printing partner should provide end-to-end support, from design and prototyping to final production and application. At Epsen Hillmer, we offer:

- Expert consultation – Helping brands select the best materials and finishes.

- State-of-the-art printing technology – Digital and traditional printing methods for maximum flexibility.

- Consistent quality control – Ensuring colors, materials, and finishes match brand standards.

Whether a brand needs limited-edition packaging, specialty finishes, or rapid reprints, having a flexible printing partner ensures long-term success in a fast-changing market.

Final Thoughts

The future of custom label printing is driven by technology, sustainability, and consumer engagement. Advancements in printing methods, smart labels, sustainable materials, and premium finishes are giving brands new ways to create more effective and engaging packaging.

Whether you’re looking to enhance brand perception, improve efficiency, or meet industry regulations, choosing the right label printing partner is key to success.

At Epsen Hillmer, we bring over a century of expertise in custom label solutions, helping brands produce high-quality, distinctive labels that stand out in the market. Our cutting-edge printing technology, expert color management, and flexible production capabilities ensure that every label meets the highest standards.Ready to start creating your Labels of Distinction with the experts at Epsen Hillmer? Contact us for a free initial consultation and a project quote.