Beverage Labels

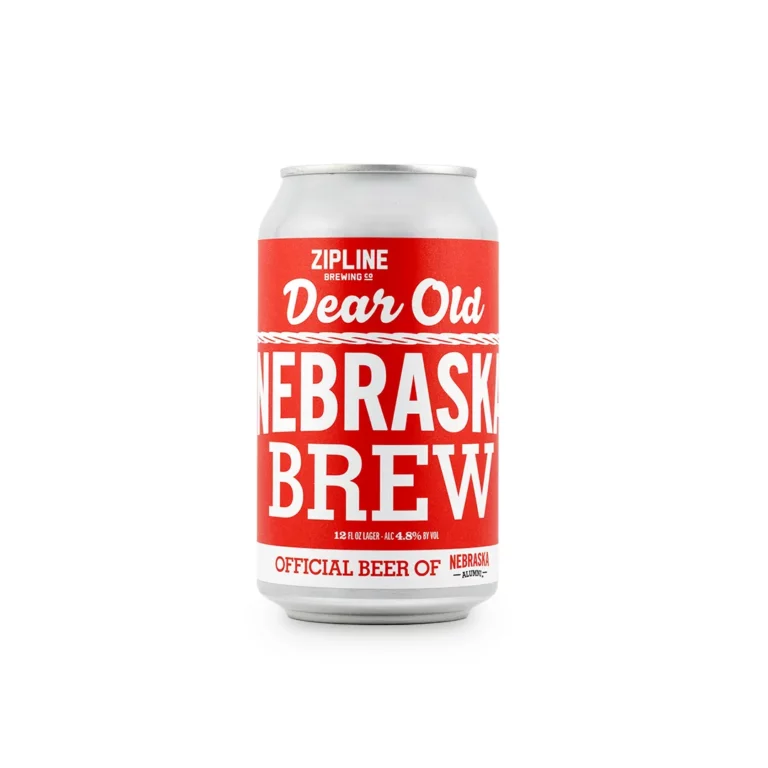

GET POINT-OF-PURCHASE ATTENTION WITH stunning beverage labels

Product Types

Water

Pop / Soda

Tea

Juice

Cocktail Mixers

Spirits

Application Types

- Cans

- Glass Bottles

- Plastic Bottles

Label Services & Capabilities

Why Epsen Hillmer

We are committed to producing

Labels of Distinction

Family owned and operated

Since 1908, as an independent and experienced label printer, we are committed to personal attention, flexibility, and direct lines of communication.

Dedicated customer support

Our customer support is responsive and individualized, ensuring that you have the best experience possible. We won’t treat you like just another client, we’ll get to know your business and build long-term relationships.

Proactive problem-solving

Just the right size

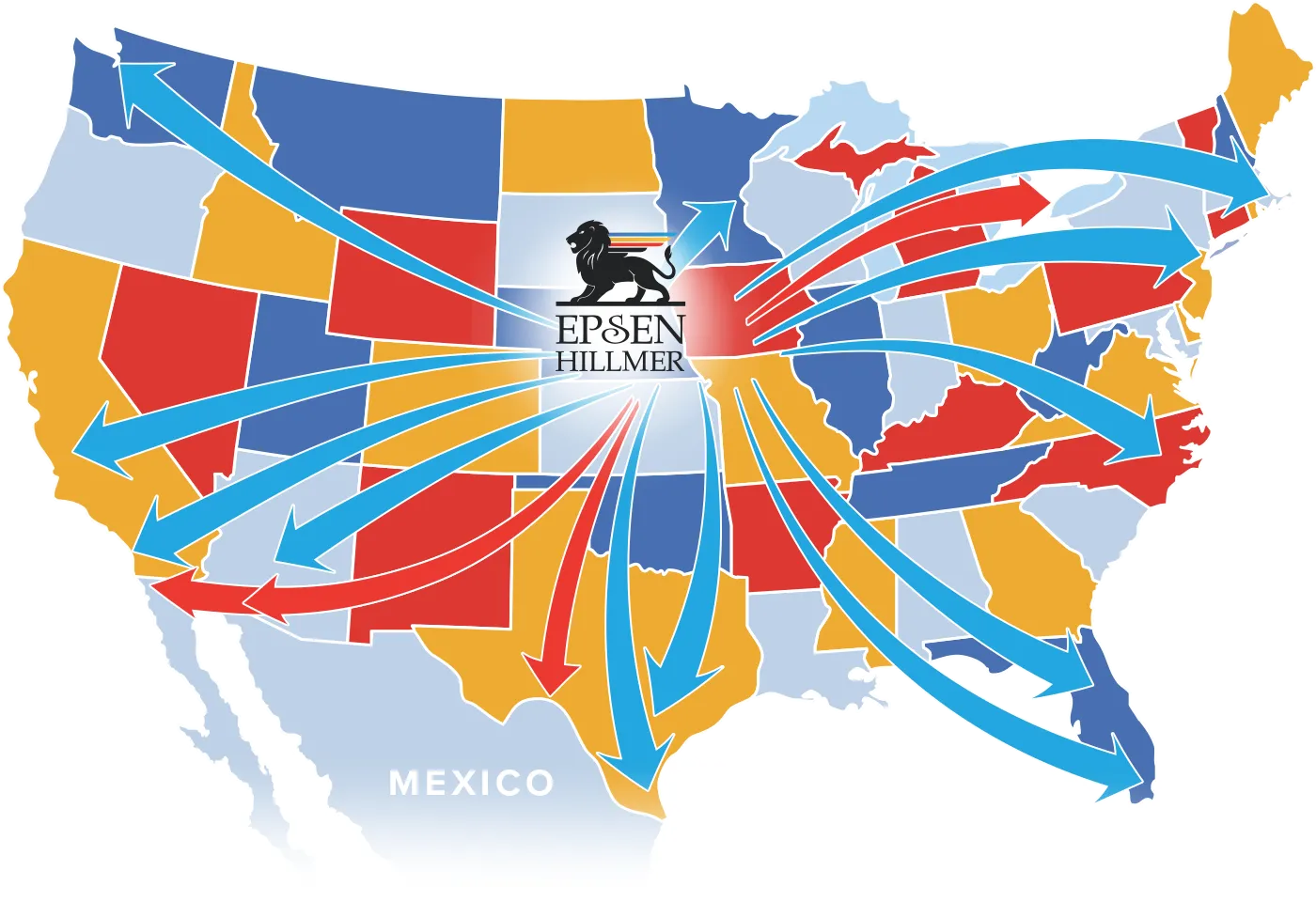

Centrally Located for

Faster Shipping

Get on the shelf and in front of consumers faster. Our Midwest location makes it easy to quickly ship your labels to packaging centers anywhere in the U.S.

Frequently Asked Questions

We can create custom-shaped labels to fit any bottle or can design. Our team works with you to ensure the label design complements the uniqueness of your beverage packaging.

Let’s print exactly what you're looking for

Talk with

our experts

See our recommendations

Make your

products pop

Newsletter

We’ll only send you something when it’s important

When there’s news, information or updates you need to know, we’ll send it directly to your inbox. Otherwise, we’ll let you focus on keeping everything running.