Managing a Diverse Product Portfolio: Labeling Challenges and Solutions

Imagine this: your team is racing to finalize the packaging for a new product launch while juggling last-minute label updates for another product line to meet updated compliance requirements. The stakes are high, timelines are tight, and the pressure to maintain consistency across your entire portfolio is mounting.

If this scenario feels all too familiar, you’re not alone. Managing a diverse product portfolio means managing a wide array of product labeling needs—each with its own set of challenges. From navigating regulatory compliance to ensuring branding consistency, the labeling process can feel overwhelming.

But here’s the good news: with the right strategies and tools, you can transform your labeling process into a streamlined, efficient operation. In this blog, we’ll explore the top labeling challenges faced by businesses managing multiple SKUs and offer actionable solutions to these common issues to help you stay ahead of the game.

The Challenges of Multi-SKU Labeling

Managing product labels might seem straightforward—until you’re dealing with dozens (or hundreds) of SKUs, each with its own design requirements, regulations, and deadlines. Here are some of the biggest challenges brands face:

- Keeping Up with Constant Changes: Product labels aren’t static. Whether you’re updating branding, rolling out seasonal designs, or incorporating new compliance details, frequent revisions can quickly become overwhelming.

- Staying Consistent Across the Portfolio: Your labels aren’t just identifiers; they’re ambassadors of your brand. Consistency is non-negotiable—customers need to instantly recognize your products, no matter how varied the lineup.

- Navigating Complex Regulations: Labeling laws and industry standards vary widely across regions and categories. Missing a critical compliance detail isn’t just inconvenient—it can be costly, leading to fines, recalls, or worse.

- Racing Against the Clock: Time-to-market pressures are real, and delays in label production can ripple through the entire supply chain. Meeting tight deadlines without sacrificing print quality or accuracy is a challenge most brands know all too well. Seasonal launches, promotional events, and last-minute changes all demand fast label production. Balancing speed, accuracy, and cost-effective operations under tight deadlines can be a significant challenge.

- Managing High Volumes of SKUs: As your product portfolio grows, so do the complexities of managing multiple SKUs. Keeping track of designs, label materials, and production schedules for dozens—or even hundreds—of labels can quickly spiral out of control without an effective system in place.

From Chaos to Control: Solutions for Labeling Success

Fortunately, you’re not alone in this. With the right strategies and tools, you can overcome these challenges and transform your labeling process into a well-oiled machine.

Centralize Your Label Management

A centralized label management system is essential for businesses with extensive product portfolios. These systems offer:

- Version Control: Ensure everyone is working with the latest approved designs.

- Centralized Asset Storage: Access all label templates, design files, and compliance documentation in one place.

- Streamlined Collaboration: Improve communication between design, marketing, and production teams.

Invest in Scalable Labeling Solutions

As your portfolio grows, your labeling strategy should scale with it. Scalable solutions like variable data printing allow you to create personalized or localized labels efficiently, without starting from scratch for every new SKU.

Automate and Streamline Label Design and Production

Automation doesn’t just save time—it minimizes human error. Tools like template-based designs and digital proofing can fast-track your process while ensuring precision.

Partner with Experts

Sometimes, you just need a pro in your corner. Working with an experienced label provider like Epsen Hillmer means you get tailored solutions, reliable support, and peace of mind when deadlines loom.

Plan for Growth

If your product line is expanding, make sure your labeling strategy can scale with it. Scalable solutions like variable data printing and adaptable templates make it easier to add new SKUs without missing a beat.

The Role of Technology in Labeling Efficiency

Technology has become a game-changer in how businesses manage product labeling. For brands managing a diverse product portfolio, embracing the right tools can simplify even the most complex labeling challenges and deliver impressive results.

Label Design Software for Precision

Advanced label design tools make it easier than ever to create professional, error-free labels. These platforms allow your team to quickly adapt designs for new SKUs or regulatory changes while ensuring compliance and branding consistency. Many tools offer built-in templates, regulatory checklists, and collaborative features, streamlining the design process from start to finish.

Variable Data Printing for Personalization

Variable data printing has revolutionized how businesses handle label customization. This technology allows you to seamlessly add unique data—such as barcodes, localized text, or batch numbers—to individual labels. Whether you’re producing small batches for niche markets or handling large-scale production runs, variable data printing enables efficient customization without compromising speed or print quality.

Cloud-Based Label Management Systems

Cloud-based platforms offer a centralized hub for managing all your label assets. Teams can access templates, compliance documentation, and production timelines in real time, no matter where they are. These systems not only reduce errors but also improve collaboration across departments and locations.

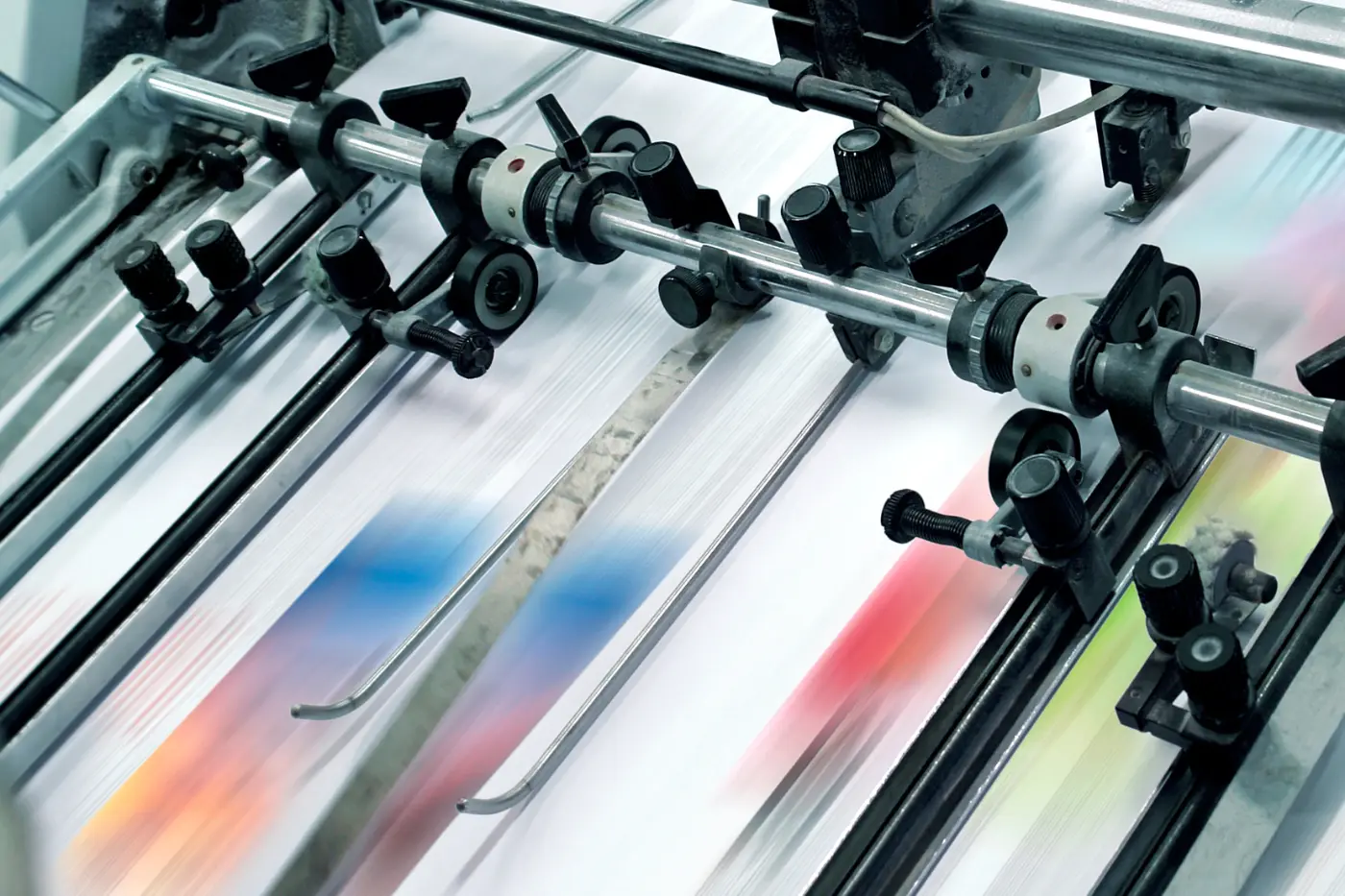

Automation in Label Printing

Automation doesn’t just streamline the design process—it also transforms production. From automated proofing to robotic printing systems, automation ensures accuracy, minimizes waste, and accelerates turnaround times. This is particularly valuable for high-volume portfolios with tight deadlines.

By integrating these label printing technologies into your labeling strategy, you can reduce manual labor, improve precision, and stay ahead in an increasingly competitive market. The result? A labeling process that’s as efficient as it is effective.

Why It Matters

Effective label management is more than a back-office task—it’s a strategic advantage. When done right, it can:

- Save Time and Money: Avoid last-minute scrambles, hidden costs and costly errors, and missed deadlines.

- Enhance Your Brand Image: Consistent, high-quality labels build trust and loyalty among your customers.

- Speed Up Product Launches: Streamlined workflows mean you can move faster, even in high-pressure situations.

Let’s Simplify Your Labeling Process

Managing a diverse product portfolio doesn’t have to be overwhelming. By taking a proactive approach to label management and partnering with the right experts, you can eliminate stress, improve efficiency, and drive better results. Ready to turn labeling headaches into a business success story? Let’s talk! Contact us today to discover how we can help your brand stand out—one high-quality label at a time.